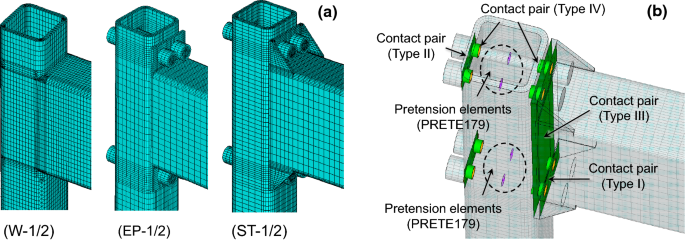

RPM Industries Aluminum Standard Shapes Catalogue IBeam and HBeam Rounded Edges Email sales@rpmindinccom Phone , Fax Request a QuoteI printed this design;The connection between the steel beams (designed by the valid standards MKS UE7140 correlated with EC3) was realized by the modified beamcolumn connection using endplate connection that was welded to beam Here, same as the previous model, endthe end of the beam At the end plate 2 holes were made (d=17mm), deployed in 4 rows,

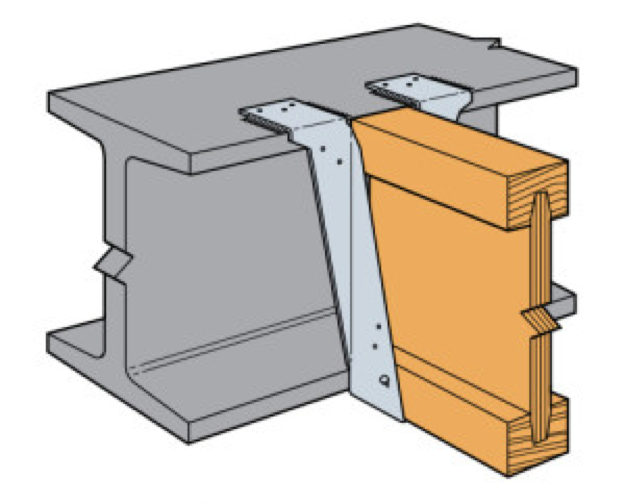

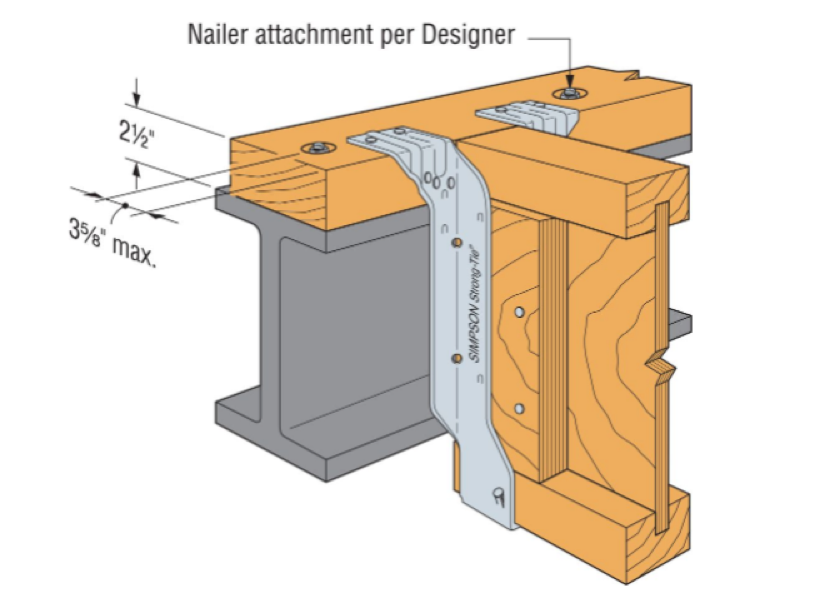

Installing Deck Girder Cantilever And Drop Beams Decks Com

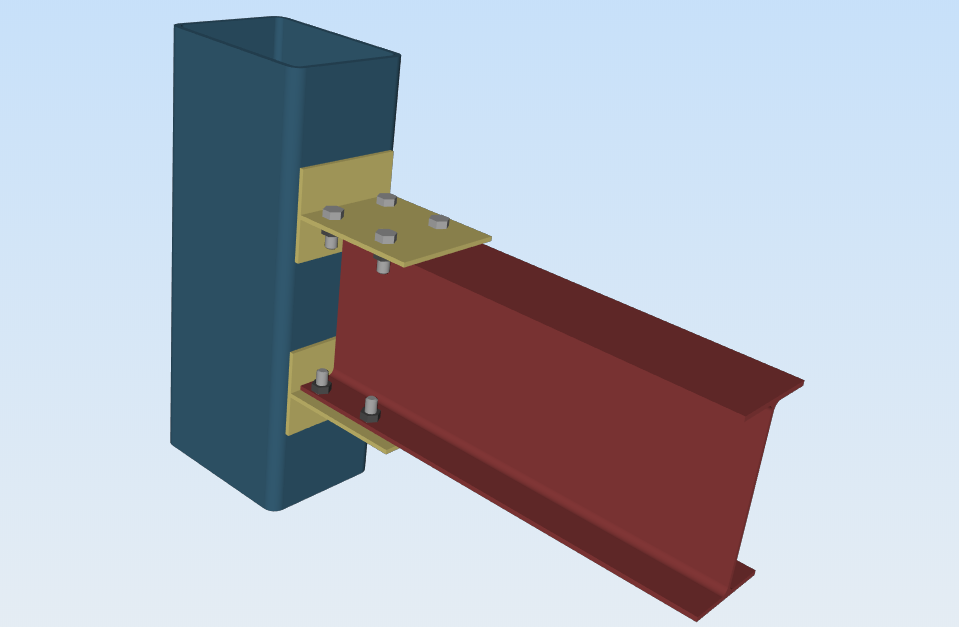

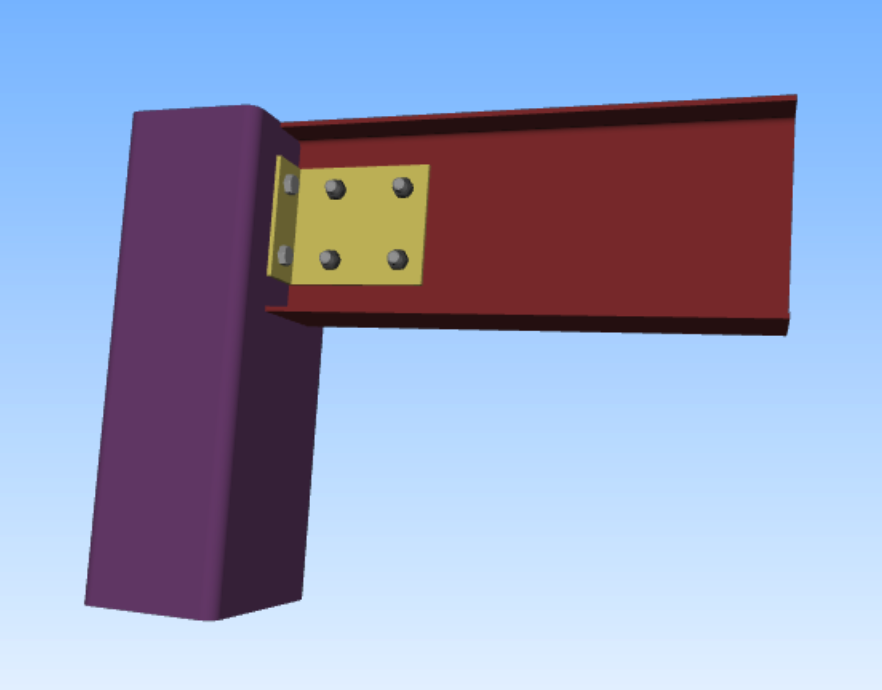

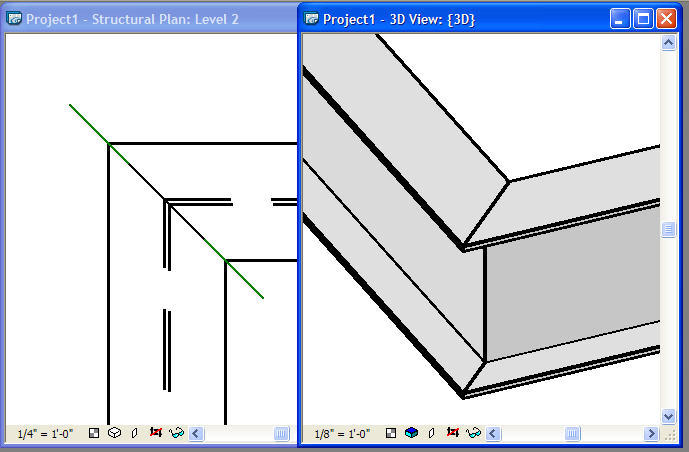

Steel beam corner connection

Steel beam corner connection-All Products From soft seating for meetings to modular pieces that make the perfect breakout pod, the way we work is changing Our collections bring people together to create collaborative, functional workplaces All NEW Booths Collaborative Soft Seating Stools & Benches Tables Work Chairs WorkCafé Browse by space Education Home office · The beam connection to the through plate is provided by longitudinal connection of the flanges to both sides of the through plate, after trimming the beam web in this region, and also two web connection plates on both sides of the through plate Moreover, two cover plates are welded to both beam flanges before beam installation to avoid overhead welding in the bottom

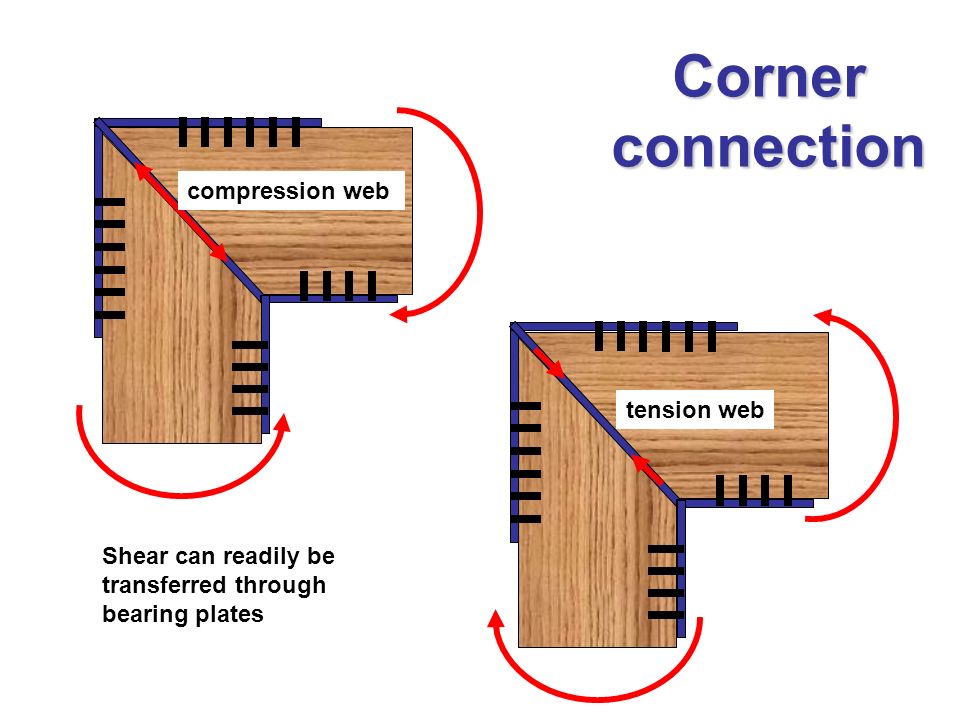

Details Of Steel Framing Ppt Video Online Download

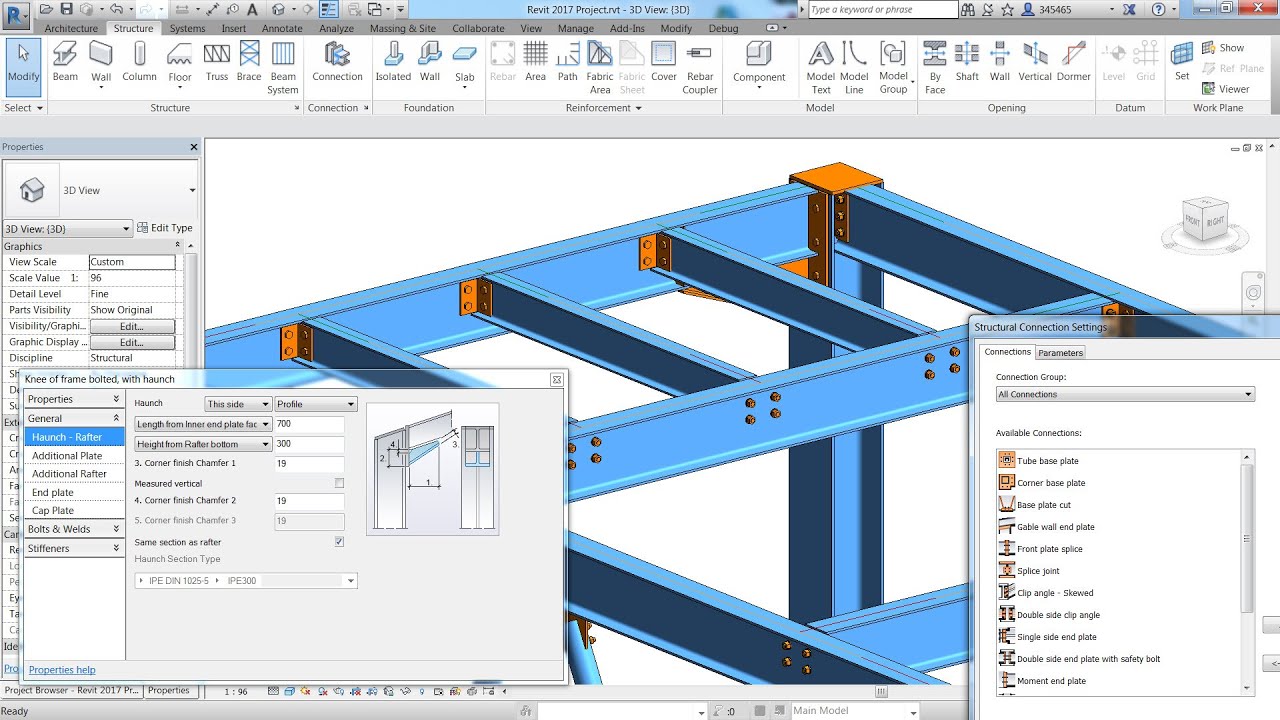

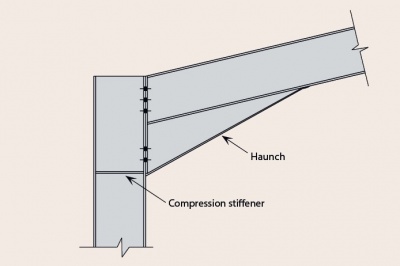

Haunch at the corners is provide, because 1 It is here that moment and shear is typically maximum 2 We can thereby have shallower section at mid span and to some length about it to increase head room where we need it most 3 We can therebyNotching at ends of beam can cause splitting at inside corner due to shear stress concentrations and induced tension perpendiculartograin stresses A notch at the end of a glulam beam should never exceed the lesser of 1/10 of beam depth or 3" and should be checked by the notchedbeam formulas in NDS* *National Design Specification for Wood Construction, American Forest and · In framed connections, an angle shelf is sometimes used to support the connecting beam during the erection, simply to facilitate the process (as shown below fig no1), though the angle shelf is not an integral part of the connection and may be removed after the connection process is over 3

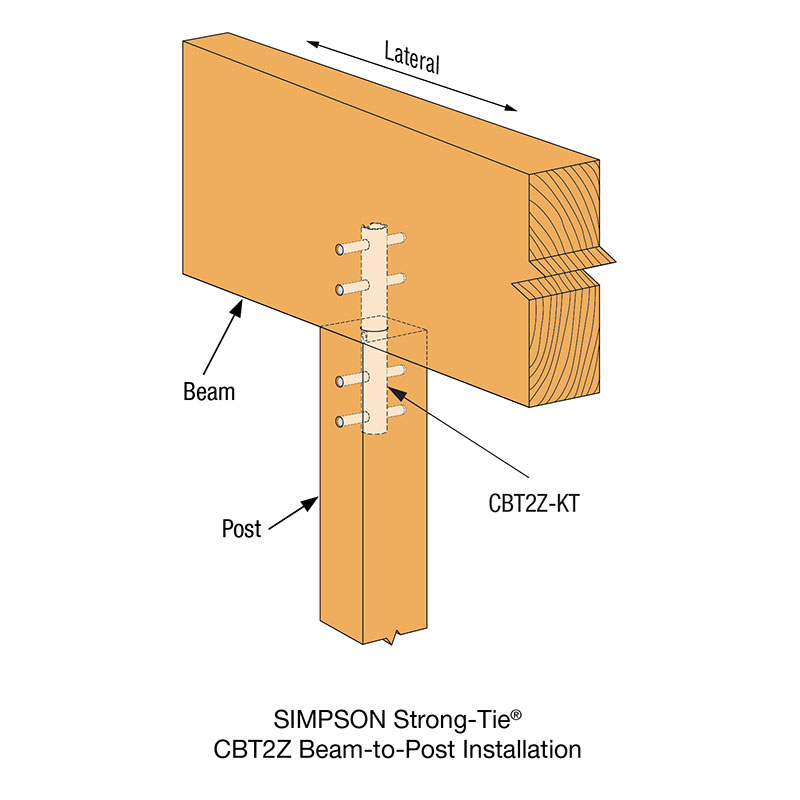

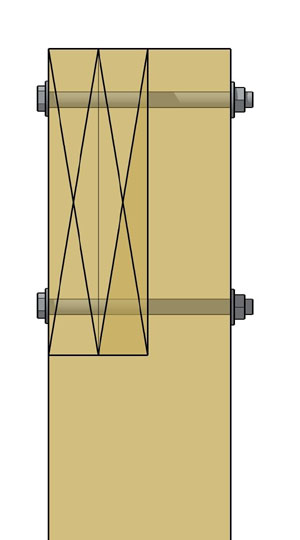

Bolts were utilized for glulam beamtobeam connections This chart shows 10 nails, all referred to as 10d, and each with potentially different performance characteristics Thus, specifying a 10d nail is not clear Photos Josh Partee Photography 10d Nails 3 x 0265 Boat Nail 27/8 x 01 Sinker Nail 3 x 0128 Bright Box Nail 27/8 x 0135 Corker Nail 27/8 x 0113 Box Nail 3 x 0148 CommonConnectors — Connext Post and Beam Connectors Our patentpending TREX Connectors are made from 6061 structural grade aluminum and anodized for extra protection Eleven different connector sizes are available to match your beam and configuration choices You will be amazed how quickly your building can be assembled with our unique TREX · Beam to beam connections could be endplates, fin plates or loose angle cleats I doubt very much that resting one beam on the other is a healthy option as that introduces bending across the flange as well as an unrestrained eccentricity that will induce twisting Sorry I can't be more specific However this is really just minor stuff that the SE can get a design out of his

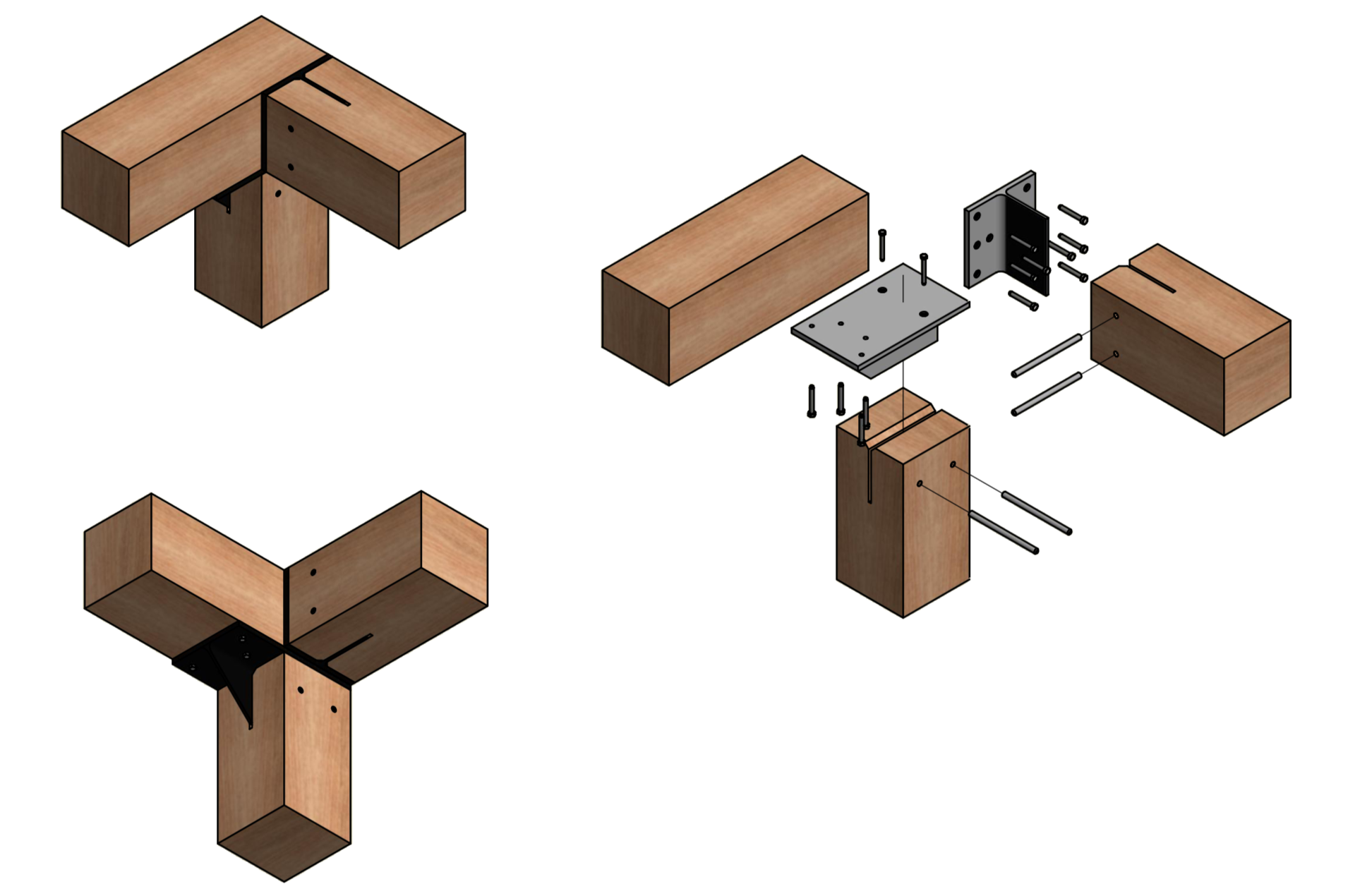

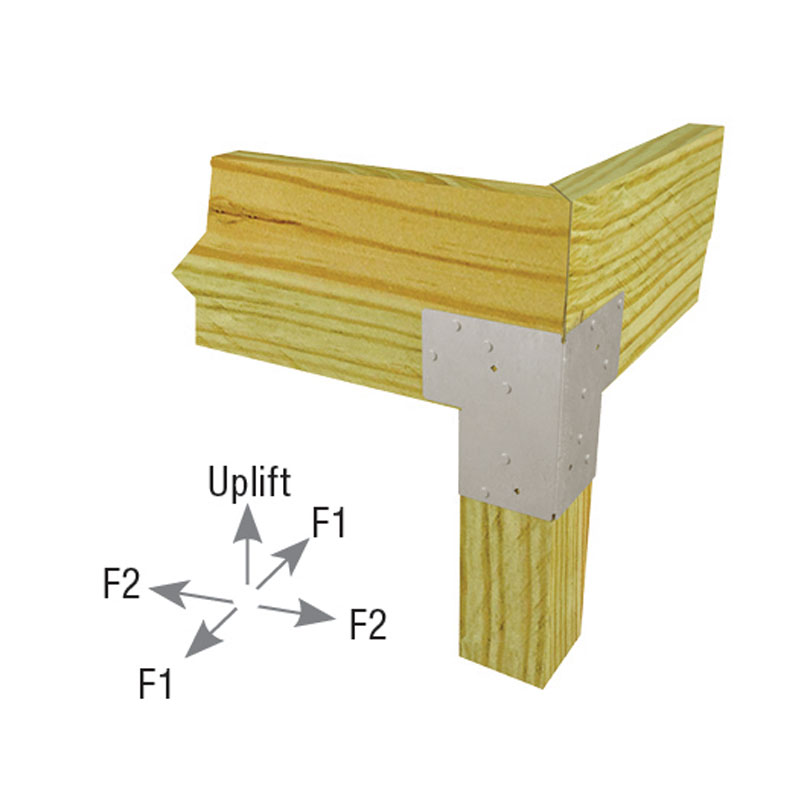

Simpson StrongTie ECCLLQ444 End Corner Column Caps provide a left connection between (2) 4x beams and (1) 4 x 4 posts when both beams end at the post Install Simpson StrongTie SDS 1/4" x 21/2" wood screws, which are provided, in all round holes (Lag screws will not achieve the same load) Please Note This column cap may be available in Hot Dipped Galvanized as a specialO aumento da espessura do pilar nas ligações soldadas demonstrouse uma alternativa eficaz no enrijecimento das ligaçõesThis research consists of an investigation above the structural behavior of connections between Ibeam and circular hollow section (CHS) columns in situation of corner columns and column loaded by 4 beams simultaneously (inside columns) The associationAluminium I beam are lengths of metal formed in the shape of a capital i that is used to distribute weight of walls and floors above an opening, and are also commonly used for structural and highly stressed applications, such as bridges, cranes, truck construction and other heavy machinery These are often referred to as RSJs, although technically speaking that name refers to rolled

How To Repair A Load Bearing Post Diy

Create Base Plate Connections With A Support Concrete Element Advance Steel 21 Autodesk Knowledge Network

· My small corner of structural engineering A blog about engineering and the design of structural steelwork Blog;Maker Beam Corner connection By M a k e r B e a m C o r n e r c o n n e c t i o n P u b l i s h e d o n A p r 0 1, 2 0 1 6 B y G A Z A L i c e n s e C o m m e r c i · Commonly, the connection is designed based on the loads at the end of the beam It is required to take strength, type and size of fasteners and strength of base materials into consideration while the connection is designed The minimum length of connection angle should be at least half of the beam clear web depth

Connections London Structural Steel Fabricators Steel Beams

1 Minute Steel Connection Design Welded Beam To Column To Beam With Stiffeners Youtube

· Beams typically rest on their posts or trimmer studs This case is no different, really, and there's no rule that says you have to have a chunk of post running up the height of the beams I'd miter the beams at a 45 degree angle so that each rests on half the post Screw them together well and toenail them into the post · An Ibeam, also known as Hbeam (for universal column, UC), wbeam (for "wide flange"), universal beam (UB), rolled steel joist (RSJ), or doubleT (especially in Polish, Bulgarian, Spanish, Italian and German), is a beam with an I or Hshaped crosssection The horizontal elements of the I are flanges, and the vertical element is the "web" Ibeams are usually made ofHBeams also called IBeams or girders are more expensive and more difficult to transport in longer lengths You can weld to Hbeams together, endtoend, to avoid the difficulties of shipping a 50foot beam, for example A good weld will provide as much or more strength as nonwelded segments beam The ability to weld beams in the field, also provides greater flexibility in your

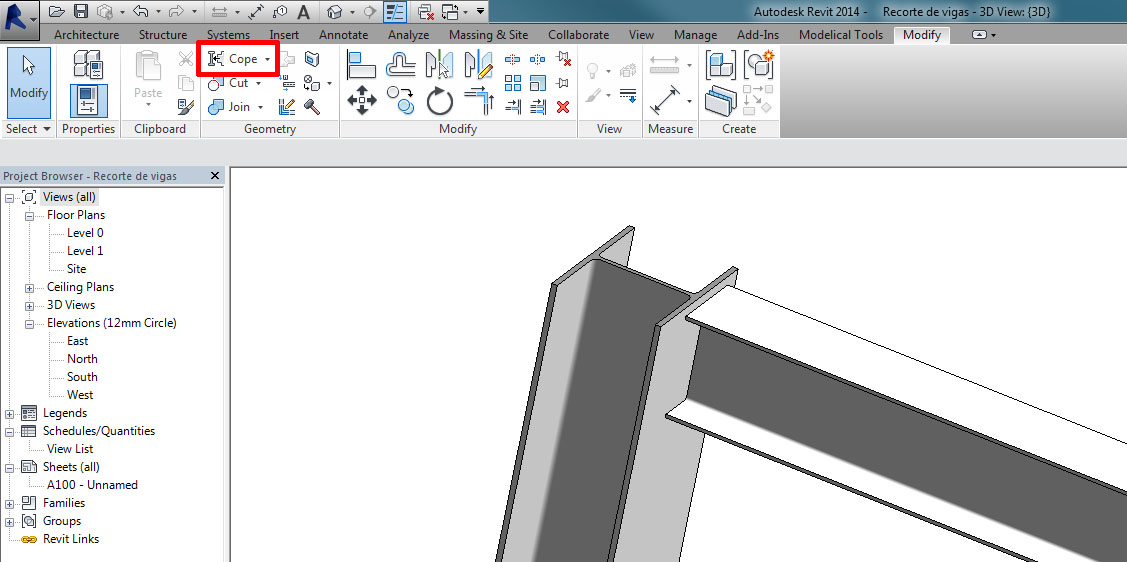

Cut Beams And Columns In Revit Modelical

Moment Connection Skyciv Cloud Structural Analysis Software

Double wall pfeifer loop connection with h12 bar and expanding foam This is how two precast walls are put together using pfeifer loops If playback doesn't begin shortly, try restarting your device Videos you watch may be added to the TV's watch history and influence TV recommendations · If you are going to have a slotted connection, I would slot the opposing corners of the tube and extend the plate through the center of the column, welding the plate to the tube at both corners of the columnByGAZA Follow user Information;

I Beam To Box Column Connection By A Vertical Plate Passing Through The Column Sciencedirect

What Is The Recommended Post Cap Or Strapping For Corner Post Under Beam And Rim Joists Home Improvement Stack Exchange

Description Our I beam corner protection strips provide excellent impact absorption capability and prevent damage from trolleys and baskets The Double D design reduces the visibility of fixings and prevents any contact with trolleysThat allows us to take a bit less wood from the beam Timber Frame Homes Post And Beam Joinery Beams Woodworking Projects Detail Knee Brace Gazebo Connection Cross Lap Joint Timber Frame HQ Cross lap joints create clean, continuous lines in a timber frame They almost make it look like the timbers are magically connected Woodworking Joints Woodworking Tips IntarsiaEnd plate beam to column and beam to beam connections Typical flexible end plate connections are shown in the figure right The end plate, which may be partial depth or full depth, is welded to the supported beam in the workshop The beam is then bolted to the supporting beam

Steel Beam Reduced Size Welded Splice Connection Detail Steel Beams Beams Weld

Types Of Steel Beam Connections And Their Details

The connection shown in Fig 2(b) is often found in moment resisting frames where the beam moment is transferred to the column The connection is also used at the base of the column where a base plate is connected to the foundation by means of anchor bolts In this connection, the bolts are subjected to a combination of shear and axial tension Moment resisting connections will beA STUDY OF RCC BEAMCOLUMN CONNECTION SUBJECTED TO MONOTONIC LOADING S S Patil 1, The exterior and corner beamcolumn joints are studied with different parameters like ie Maximum principle stress, Minimum principle stress, Displacement, Deformation also studied end conditions of beam column joint ie fixed end conditions, Hinge end conditions and Stiffness variation of beamA French bridge rehab project needed to connect Ibeams together temporarily without deforming the permanent beams with welding BeamClamp became the perfect engineered connection system Offset Connections for IBeams Connecting Ibeams

Details Of Steel Framing Ppt Video Online Download

Ozco Project 334 10x10x16 Corner Pergola Laredo Sunset 8 Post To Beam Ozco Building Products

I Beam Corner Junctions Global Truss professional IBeam truss corner junctions for IBeam corner connections All Global Truss corner junctions and segment pieces are machined with male female connection points Easy assembly and secure fitting attachment points insure ridged straight connections and reliable performanceSimple post and beam frames may use half lapped connections, while timber frames will use a variety of mortises, tenons, dovetails and shoulders Heavy Timber construction uses beams and stringers that are connected with bolts and gusset plates or traditional wood joinery with pegs and dovetails The element that most defines a timber framer is the quality, integrity and strength of · I am working on a connection detail at the corner of a building, where an LVL cantilevers 1' and picks up a steel beam Also on top of this junction, there is a column load So that's why not looking into Simpson hanger's in this particular case, however in these situations is it common to provide a bent prefab saddle plate (Lshape) and fasten together with bolts?

End Plate Stiffener Connection For Shs Column And Rhs Beam In Steel Framed Building Modules Springerlink

Schock Blog Blog Archive Exterior Steel Beams That Break Thermal Bridging

Construction Beam to Beam connection training video from the Corus BCSA training packMaker Beam Corner connection 432 Download;Here we will review the following connectors used in Wood Framing & Deck & Porch Construction, Structural Joist Hangers, Brackets, & Connectors for posts, beams, joists, railings, ledgers, etcDeck & Porch Post & Beam Connectors steel post cap connectors, plywood post to beam cleats, scabs, other connectors

Simpson Strong Tie Eccll L Shape End Column Cap For 6x Post 6x Beams Skewed Left Eccll666 The Home Depot

Structure Steel Beam Home Building In Vancouver

Single sided beamtocolumn joint configuration, bolted endplate connection M V 15 3 IPE2 HEB140 1 60 10 30 80 30 240 4 M16 140 p=60 u=10 5 w= To be evaluated Design moment resistance , initial stiffness 0 1 1,0 1,0 M M J J Material S 235Cause splitting at inside corner due to shear stress concentrations and induced tension perpendiculartograin stresses Split Split FIGURE 1 BEAMTOBEARING CONNECTIONS EWS,TN,T3000 2/23/00 910 AM Page 4 5 Correct Incorrect Discussion 1/2" minimum air space shall be provided between wood and masonry surface 1/2" minimum air space shall be providedImages Connections the basics June 02, 18 by Martyn Pysanczyn This is to be the first in a series of articles, where the aim is to introduce the different types of steelwork connections, when the various types should be used, and what ought to be

Is It Structurally Sound To Cut An I Beam To A T On One End Engineering Stack Exchange

Joist Hangers Post Beam Framing Connectors Guide To Choosing Using Porch Deck Structural Connector Brackets Plates

Concrete joints in vertical position, eg beam to column or to wall connections, and horizontal ones, base plates The behaviour of components in terms of resistance, stiffness, and deformation capacity is summed up for components in concrete and steel parts header studs, stirrups, concrete in compression, concrete panel in shear, steel reinforcement, steel plate in bending, threaded · This video shows how the BeamClamp IBeam Connection system comes together to join two IBeams together without welding or drilling Find our more about thiIf beams with moment connections frame into both column flange(s) and web, try to use the same depth for all beams This eliminates interference where stiffeners are required Skewed moment connections at columns, especially for beams framing into a column web, can be difficult to make Modifying the framing, rotating the column, or slightly moving the beam end can greatly simplify

Connectors Connext Post And Beam

Connectors Connext Post And Beam

4 In connections to column webs, the beam flange may also need to be coped (removed) to allow the connection to be effected (Figure 7) 5 Fabrication of this type of connection requires close control in cutting the beam to length and adequate consideration must be given to squaring the beam ends such that both angle cleats are parallel and the effect of beam camber does notWelded beamtocolumn connections can be prepared in the fabrication workshop with a bolted splice connection within the beam spam, at a position of lower bending moment Welded connections are also used for the construction of buildings in seismic areas Other types of moment resisting connections include Splices in columns and beams, including apex connectionsOur concrete connections, composite structures and other solutions offer improved efficiency Selected Beam Connections Products for Precast Foundation Connections Column Connections Beam Connections Slab Connections Slab Openings Wall Connections

Post Beam Construction Introduction Part 1

Installing Deck Girder Cantilever And Drop Beams Decks Com

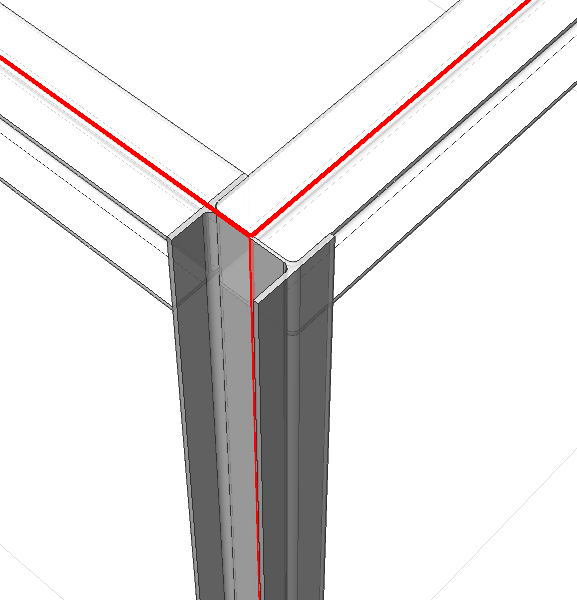

· The miter joint option is only available to beams of the same Type The 'blue dots' representing the ends of each beam have to be joined In certain cases the Reference Plane method is still a good option for controlling joints, but for simple mitered joints with beams of the same type, the Beam/Column Joints method is the way to goA print friendly corner connection for Makerbeam 10mmx10mm, the countersink keeps the nuts and screw ends protected, nevertheless it looks better ), right? · The size of the list can be controlled through a set of buttons located on the topright corner of the list From here you can add or remove rules, and change their position in the list The order in the list is important the lines are applied by going from top to bottom, so if the quick connection matches a combination set at line one for a set of beams, it will skip the following

1 Revit 19 Insert Parametric Steel Connections Youtube

Renovate Forums

Home » Tech Corner » IBeam and HBeam Connecting Rods Explained IBeam and HBeam Connecting Rods Explained May 13, maxtorque 0 Tech Corner By BRIAN WAGNER MAY 11, Connecting rods are probably one of the easiest parts to understand inGeneral advanced and dynamic sketch of the designed connection model in an editable DXF format, which includes a bill of materials crosssections for the beam are Ibeam sections possibility of the design and verification of pole/column base obtained from ArCADia RAMA structure model column anchored in the foundation block at a straight angleBeamtobeam connection with a long double cope at the supported beam For design purposes, the coped region can be modeled as a short beam with a length equal to the cope length In addition to the constant shear force, , the cope is subjectR ed to a linearlyvarying moment The maximum moment is at the face of the cope, causing compressive flexural stresses at the reentrant corner

Timber Joinery Wood Beams Wood Turning Wood Corner Joints

Column And Beam Construction Tips

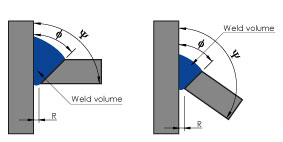

· Steel connection design and s steel beam to column connections with i beam to box column by a short stub calculated steel connections Types Of Joints Beam To Column ConnectionAdConnection shown below, L Wto address shear lag in such connections • When a weld extends to the corner of a member it must beWhen a weld extends to the corner of a member, it must be continued around the corner (an end return) – Prevent stress concentrations at the corner of the weld – Minimum length of return is 2w BMA Engineering, Inc – 6000 15 Effective Area of Welds

Post Beam Construction Introduction Part 1

Performance Evaluation Tests Of Welds And Beam To Column Connection Welds Jfe Techno Research Corporation

Corner Of Steel Beams Stock Photo Image Of Level Columns

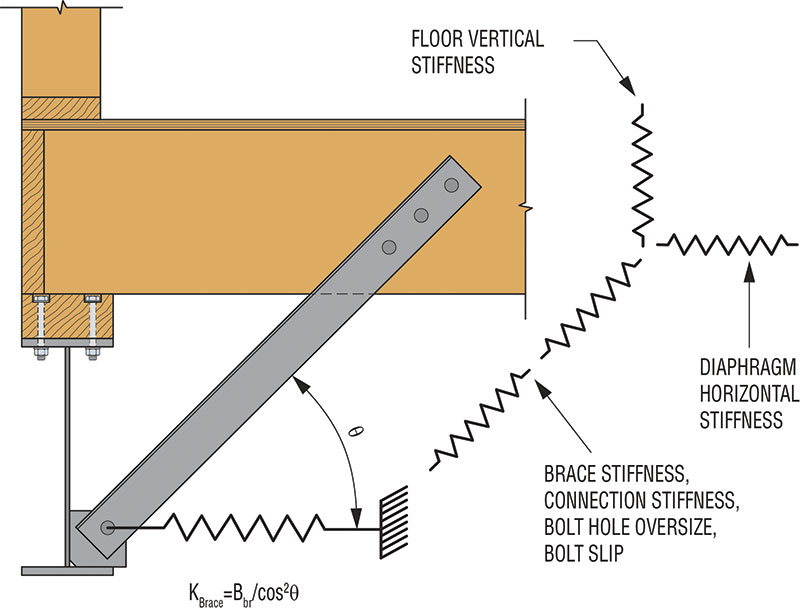

Structure Magazine Building Resiliency

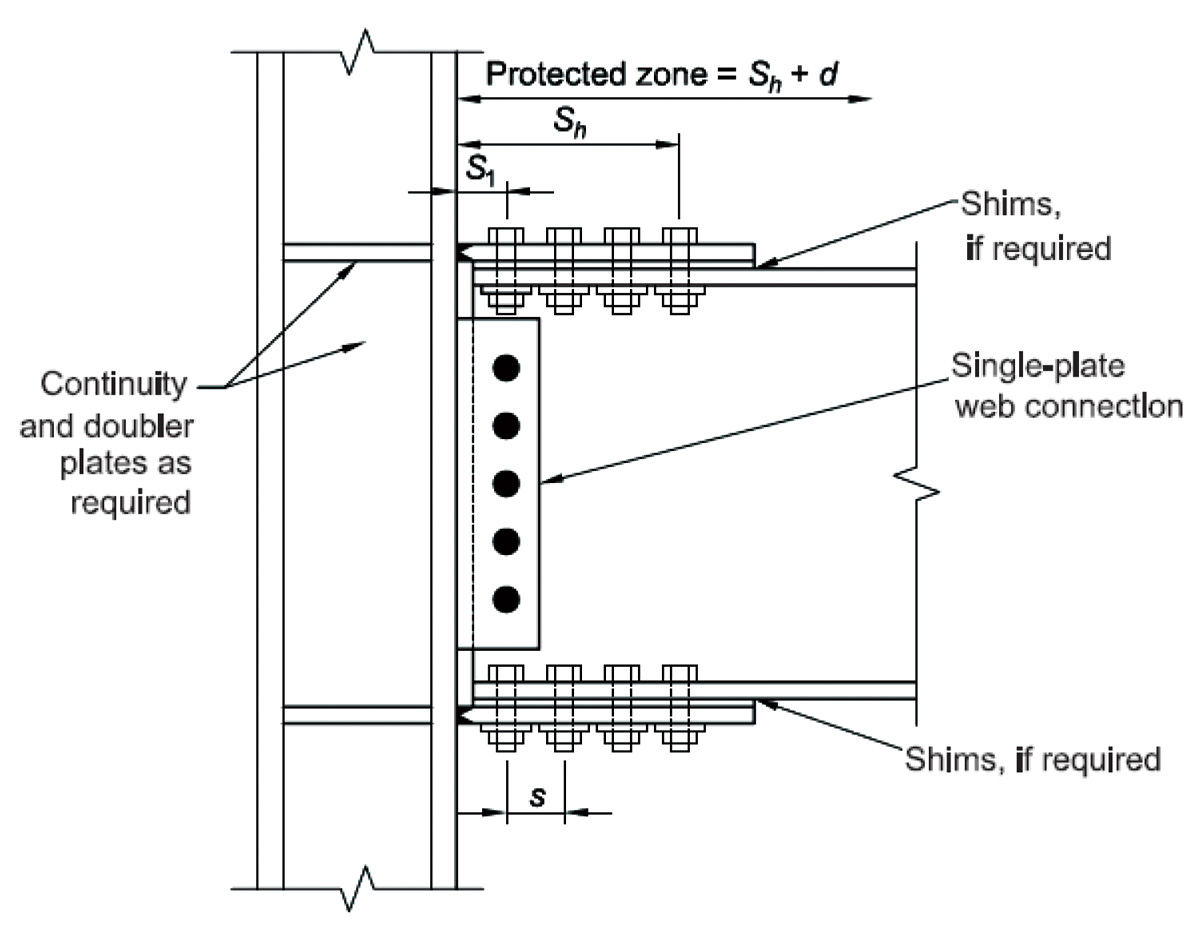

Structure Magazine Unanticipated Stresses And The Welded Flange Plate Moment Connection

Structure Steel To Wood Home Building In Vancouver

Joinery Post And Beam Barns The Barn Yard Great Country Garages

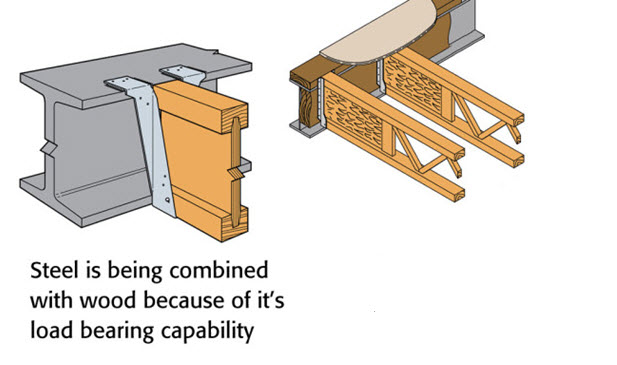

Wood To Steel Connections Making Sure It S Done Right Triforce Open Joist

Beam To Beam Welded Joint Structural Engineering General Discussion Eng Tips

Traditional Post Beam Joinery Handcrafted Timber Connections

Structure Steel To Steel Home Building In Vancouver

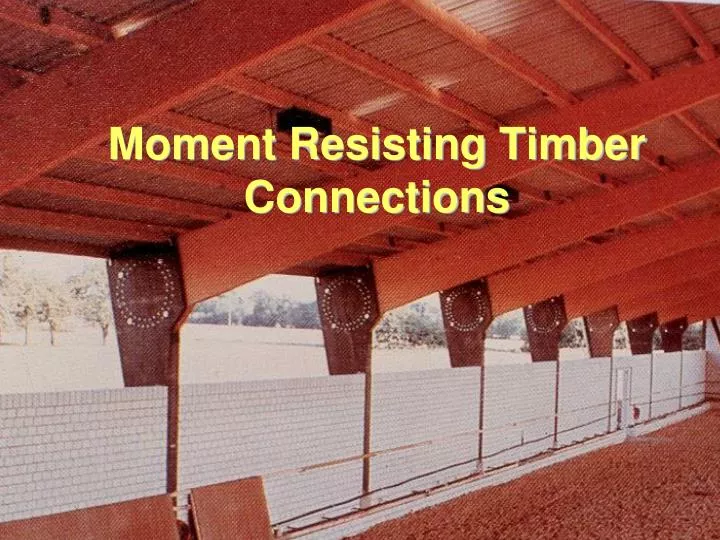

Moment Resisting Timber Connections Ppt Video Online Download

Wood To Steel Connections Making Sure It S Done Right Triforce Open Joist

Post Bracket Bottoms And Tops Cutting Edge Metals Inc

Steel Project Case Study Gallery Ocad Ontario College Of Art And Design Addition Alsop Robbie Young Wright Toronto

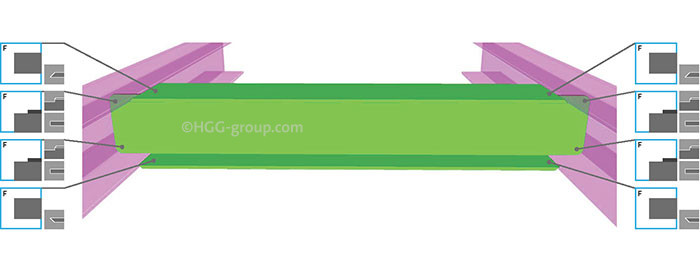

How To Make Strong Welded H Beam Connections Hgg 3d Profiling

Mitek 6 X 6 Steel Post Beam Corner At Menards

Recommended Detailing At Corner Connection Region Of Brbf Download Scientific Diagram

Shear Connection Skyciv Cloud Structural Analysis Software

Metal Buildings Column And Beam Steel Frame Structures

Revit Oped Revit Structure Miter A Steel Corner Connection

Column And Beam Construction Tips

Concept Design Steelconstruction Info

Large Wood Beam Patio Corner

Upn Channel X Bracing Corner Connection Detail Structuraldetails Store

Post And Beam Joints Timber Frame Hq

Hss Column To W Beam Connection For Frame Structural Engineering General Discussion Eng Tips

How To Make Strong Welded H Beam Connections Hgg 3d Profiling

Corner Connection With Download Scientific Diagram

Post Bracket Bottoms And Tops Cutting Edge Metals Inc

Pbc Series Mitek Residential Construction Industry

Ppt Moment Resisting Timber Connections Powerpoint Presentation Free Download Id

Types Of Steel Beam Connections And Their Details

Stronger Post To Beam Connections Jlc Online

How Can I Attach Angled Beams To A Post Home Improvement Stack Exchange

I Beam Vs Square Tube For Columns Structural Engineering General Discussion Eng Tips

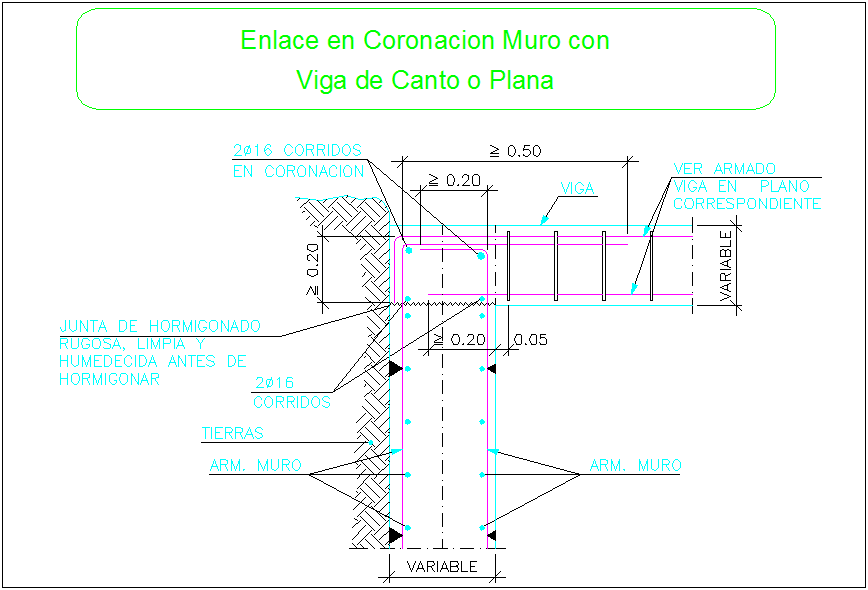

Beam Column Connection With Corner Beam Or Flat Detail Section View Dwg File Cadbull

Top 10 Deck Building Mistakes Fine Homebuilding

Structural Steel Bricsys Support And Help Center

How To Ways To Connect Beams When Building

Structural Steel Connections In Revit 17 And Advance Steel 17 Youtube

Steel Joist To Steel Beam Connection Google Search Steel Beams Beams Steel

Engineers Corner Moment Connections Designed For The Plastic Moment Cisc Icca

Vertical Diagonal Chs X Bracing Corner Support Connection Concrete Column Vertical Diagonal

Wood To Steel Connections Making Sure It S Done Right Triforce Open Joist

The Difference Between Timber Framing And Post And Beam Timber Frame Hq

Joining Beams Over Posts What Are The Options

Steel Connections In Revit 17 F Bim And Beam

Post Beam Construction Introduction Part 1

Beam Timber Frame Hq

Diagram Of The Connection Of The Steel Ring Beam To The Masonry Wall Download Scientific Diagram

Maker Beam Corner Connection 3d Models Stlfinder

Bim Beam Tom S Corner

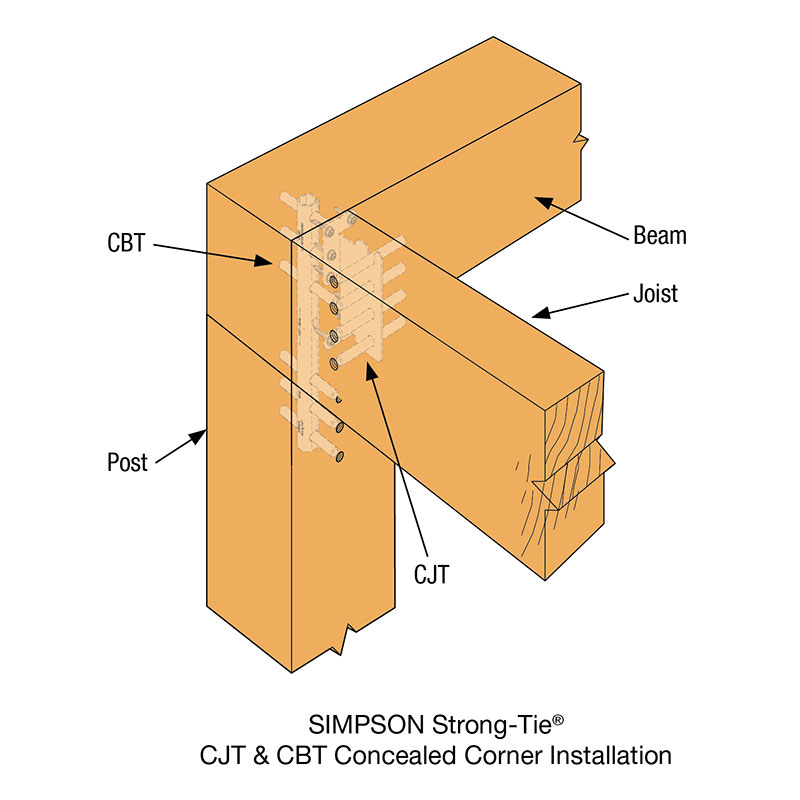

Cbt Concealed Beam Tie Strong Tie Together We Re Helping Build Safer Stronger Structures

Solved Connecting Steel Beam And Column Using Cap Plate Autodesk Community Revit Products

Structure Steel To Concr Home Building In Vancouver

What Size Should The Reinforcing Welded Corner Be Diy Home Improvement Forum

Modules Connected At Different Joints A Corner Joint With 2 Columns Download Scientific Diagram

Moment Resisting Timber Connections Ppt Video Online Download

Concept Design Steelconstruction Info

Solved Shear Plate Of Column Beam Connection Autodesk Community Advance Steel

Alternative Bond Beams

How Should I Connect Two Beams To A Post At A Corner Home Improvement Stack Exchange

Moment Resisting Timber Connections Ppt Video Online Download

Steel Structures And Connections In Revit Tutorial Youtube

Creating Strong Post To Beam Connections Decks Com

Structure Steel To Wood Home Building In Vancouver

Corner Beam Connection Inverted Hanger Post And Beam Wood Framing

Structure Steel To Concr Home Building In Vancouver

Cbt Concealed Beam Tie Strong Tie Together We Re Helping Build Safer Stronger Structures

Structure Steel To Wood Home Building In Vancouver

View Of Corner Moment Connection At The Core And Wood Beam Support Detail

0 件のコメント:

コメントを投稿