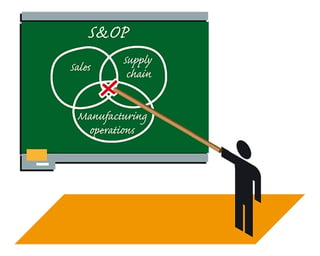

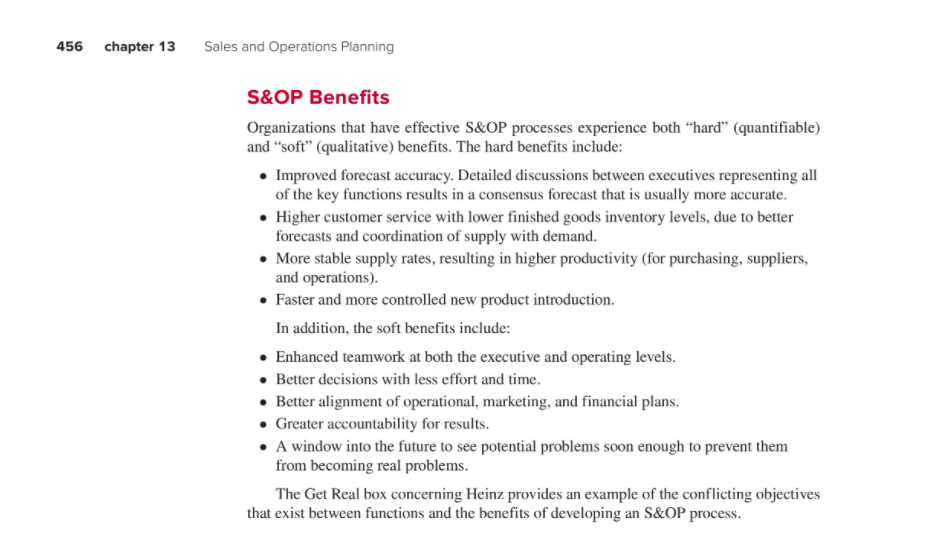

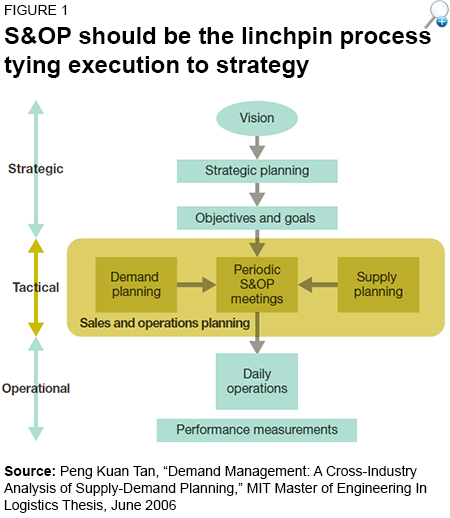

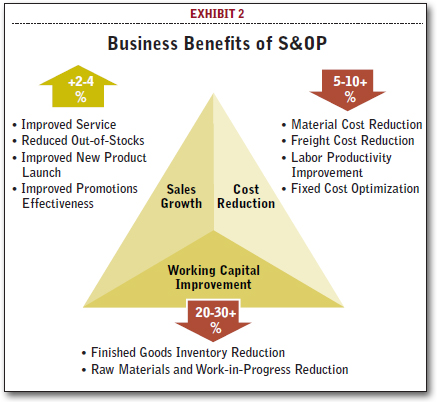

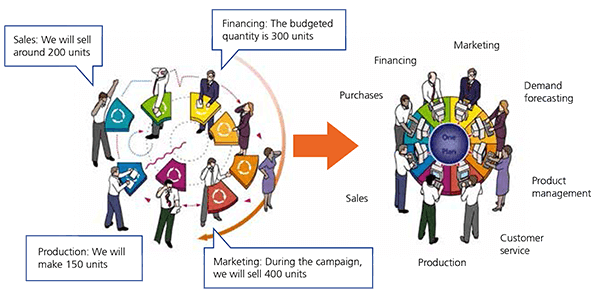

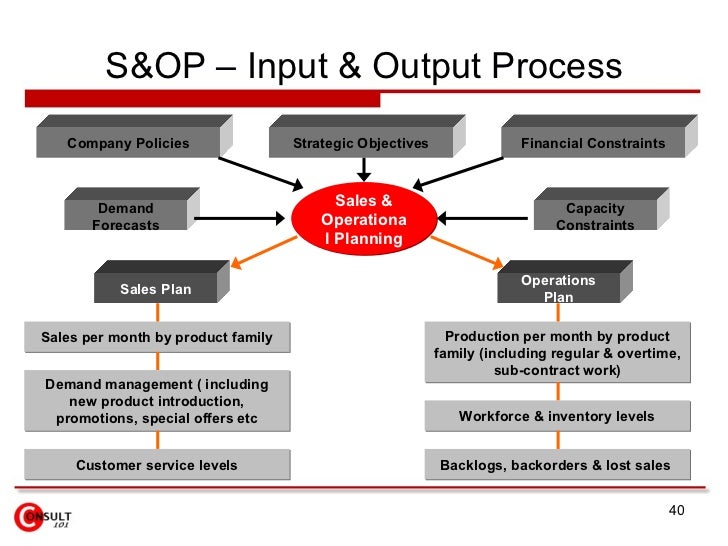

Sales and Operations Planning (S&OP) is a powerful decision making tool for business executives as well as line managers According to Tom Wallace, "S&OP enables the company's managers to view the business holistically and gives them a window into the future" Positive results that companies have gained from S&OP include hard benefits such as improved customer service01/01/19 · S&OP is described as a crossfunctional long term planning process that links different business plans into one integrated set of plans with the main purpose of balancing supply and d mand and linki g the strategic plans to the operational plans of the firm09/01/21 · If your company has ever experienced the frustration of product stockouts in key markets while inventory builds up in other markets—or on warehouse shelves—a dysfunctional S&OP process is usually to blame At its core, S&OP planning is about managing supply and demand Doing this effectively requires three things better information flow

Isn T S Op Really Inventory Planning Navigate The Future

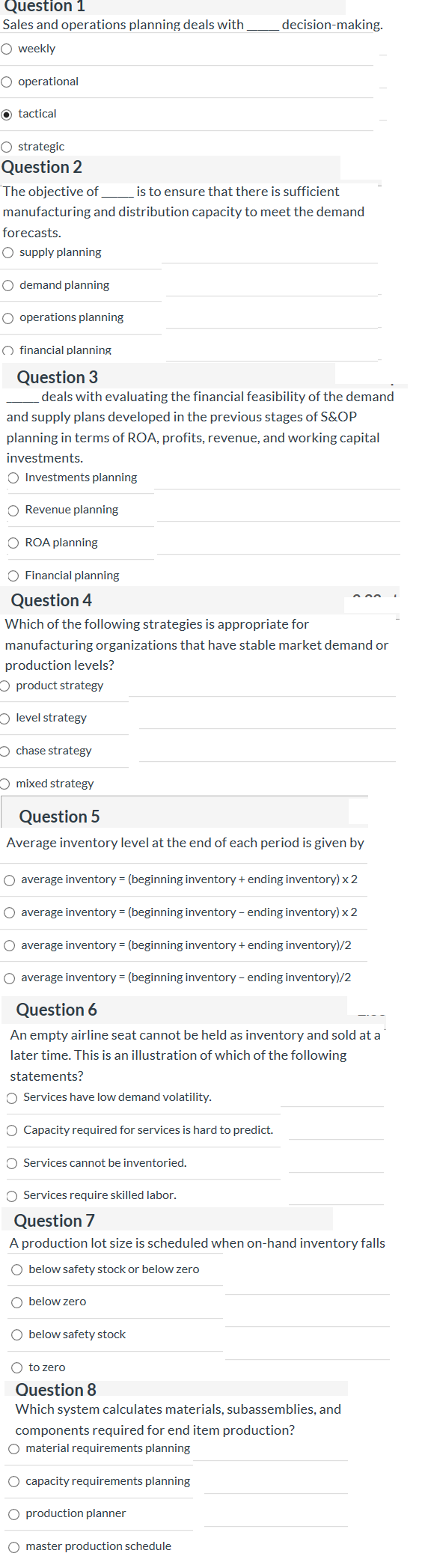

S&op planning is usually done by

S&op planning is usually done by-07/05/ · Sales and operations planning is a process which helps in managing the demand and supply of manufacturer by collaborating the sales and operations department to create a single production plan It is also referred to as aggregate planning, and executivelevel management meets regularly to review the projections for demand and supply and financial impact, whichA budget review S&OP is based on current inputs concerning demand and supply;

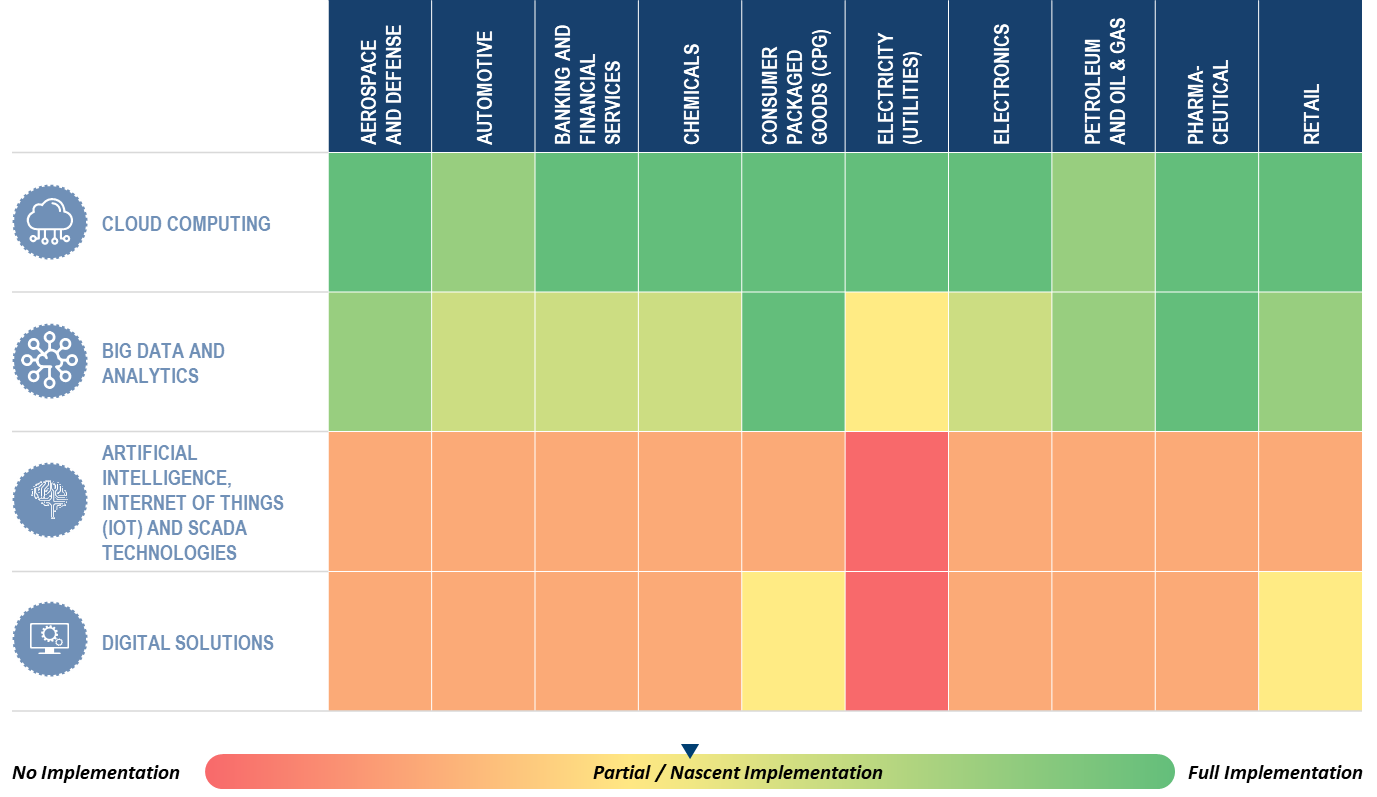

Is Sales And Operations Planning A Digital Age Process Enterra Solutions

In our knowledge article What is S&OP?, we explained what sales and operations planning (S&OP) is and its many advantages To sum up, S&OP is the creation of a unified, consensusbased business plan that enables organizations to control inventory costs while vastly improving service levelsSales and Operations Planning (S&OP) is a corporate practice intended to deliver superior supply chain execution by leveraging a deeper alignment with other divisions beyond supply chain most notably sales, finance and productionCommon misconception that deploying S&OP (or more likely, its latterday incarnation, Integrated Business Planning), will fix these issues Integrated Business Planning is a powerful decisionmaking process that sits at the heart of the Oliver Wight Integrated Business Model (Figure 1) and is the means many organizations now choose to run their entire business However, as the Model

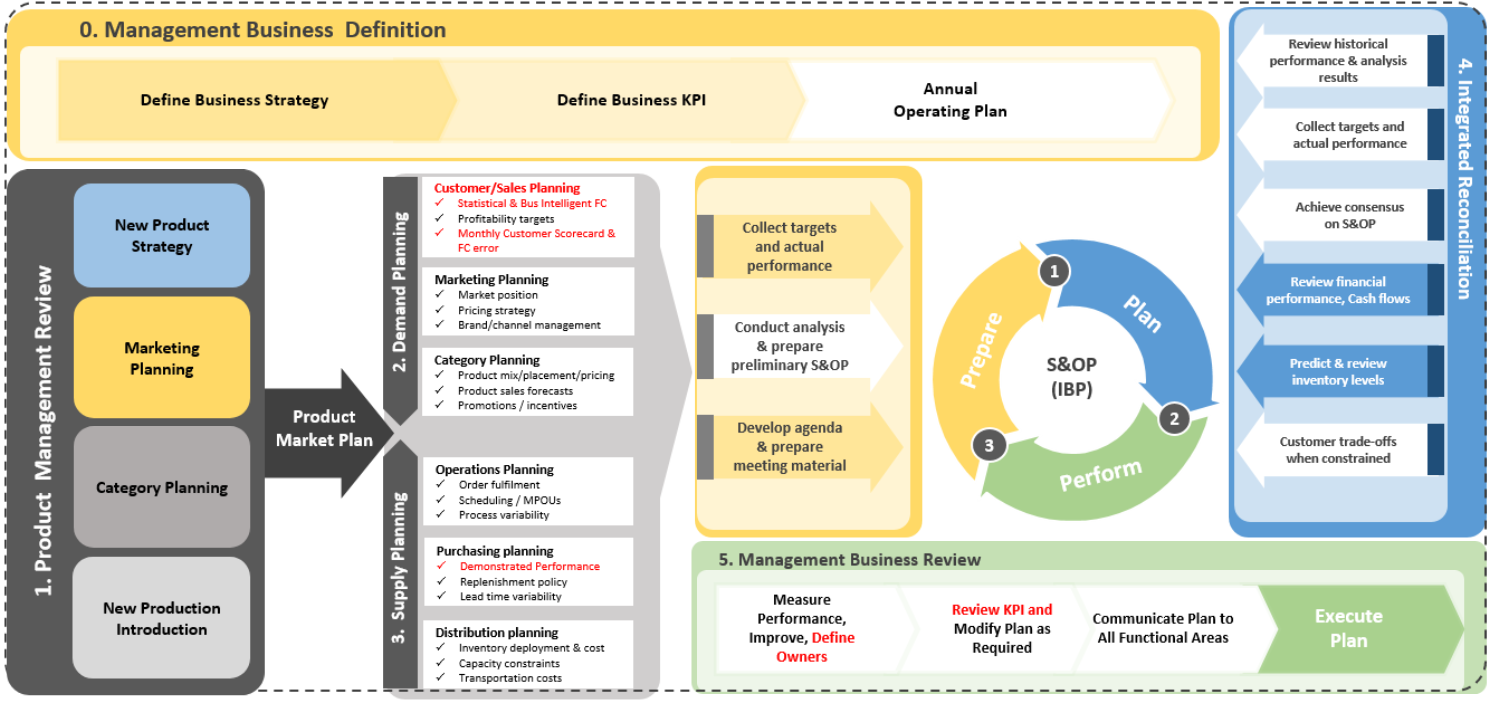

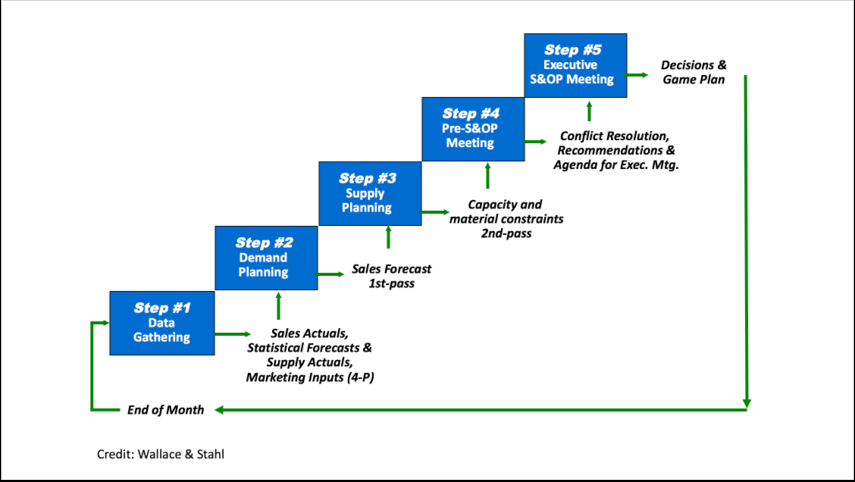

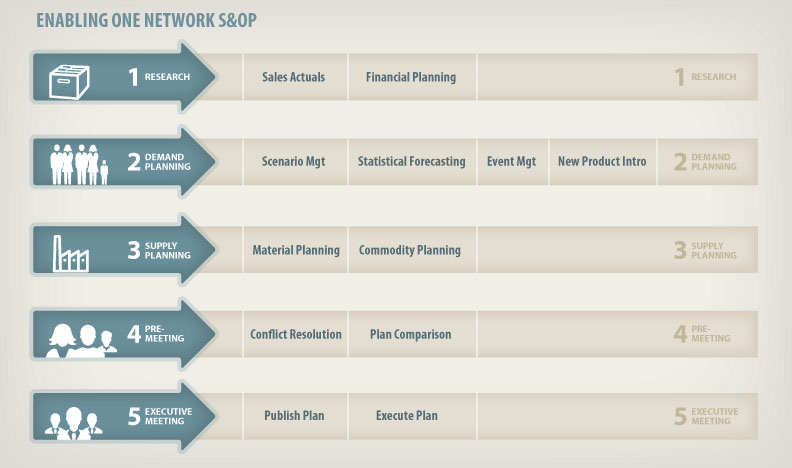

01/05/16 · There is usually one department creating decks and presenting the figures not only for their area but also the information for other functions and sites AS&OP, or sales & operations planning, is a monthly integrated business management process that empowers leadership to focus on key supply chain drivers, including sales, marketing, demand management, production, inventory management, and new product introductionSales and Operations Planning Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are conduct 1

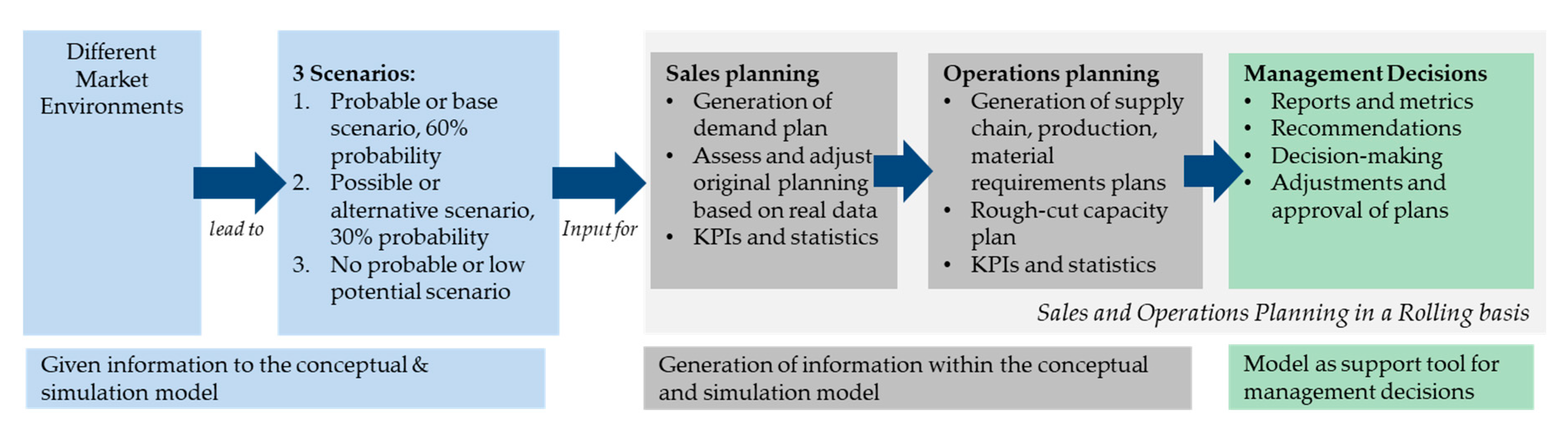

Include your key trading partners S&OP plans include key channel partners and critical material suppliers for an integrated business plan that meets your annual operating plan targets;There are three major types of planning, which include operational, tactical and strategic planning A fourth type of planning, known as contingency planning, is an alternative course of actionA key assumption at this point is that you have a

Sales And Operations Planning A Guide For Small Businesses

Back To Basics The Importance Of S Op

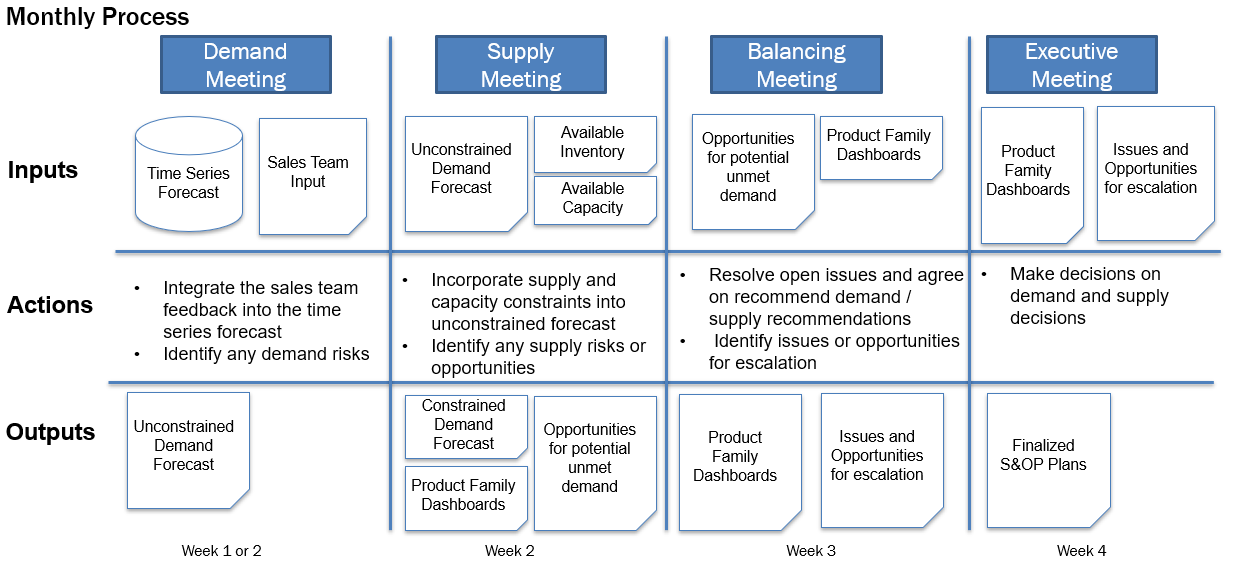

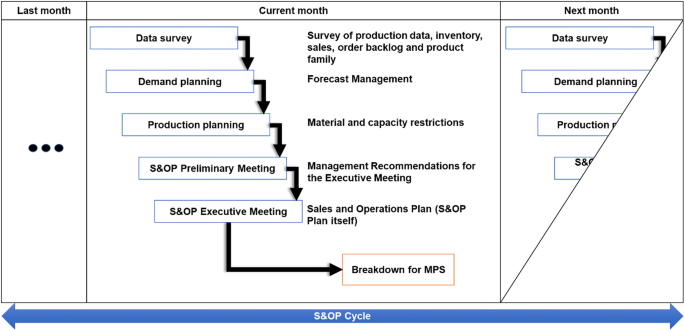

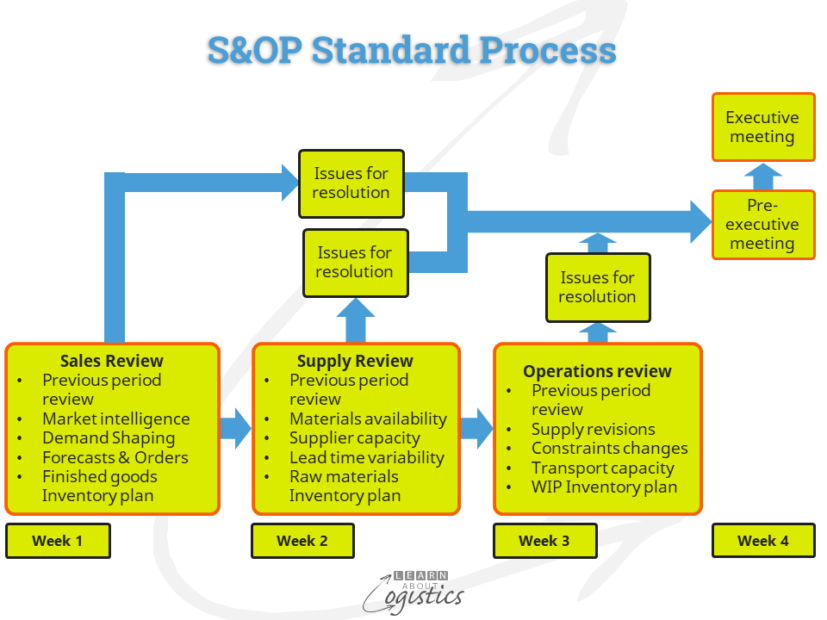

Perform multilevel supply planning (HeuristicS&OP planning, at the simplest level, is carried out in a monthly cycle of meetings and premeeting preparation and broadly works as follows Week 1 – Demand Planning A midtolong term volume based demand forecast is generated and agreed with all key stakeholders The stakeholders may include sales, marketing, finance and new product introduction Week 1 effectively answers theFew organizations find S&OP an easy process Usually it takes time and practice, often over many months or years, to create a continuous highperformance sales and operations planning (S&OP) practice Before positive results occur, an organization must develop ways to meet the demands that S&OP requires This involves improving communication and soft skills, integrating relevant

S Op Effectiveness Recommendations To Make The Leap Supply Chain Shaman

Sales And Operations Planning For The Food Supply Chain Case Study Sciencedirect

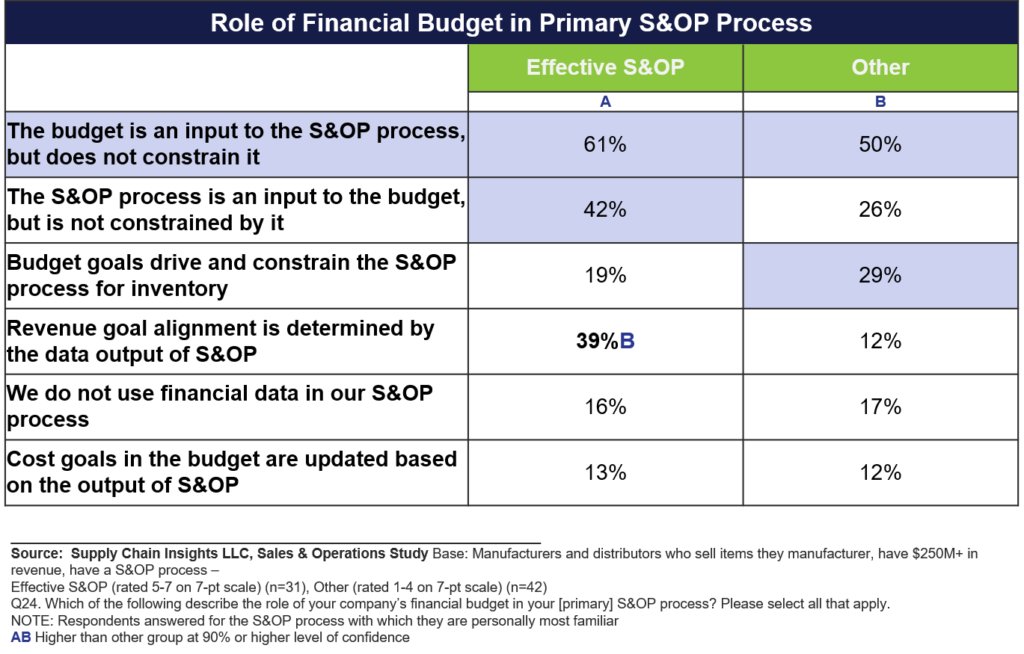

Therefore S&OP is an input to budget updates, but should not be constrained by budgets;Account for Variability in the Supply Chain;06/03/14 · If a planning application is called in, the decision on whether or not to grant planning permission will be taken by the Secretary of State, usually after

Getting To Grips With Sales And Operational Planning Bloor Research

Sales Operations Planning Why Is S Op Important

S&OP is about doing what is best for the company as a whole, and therefore the overall purpose of the S&OP process is to establish one overall plan Sales wants to have plenty of inventory in order to keep customers happy Operations wants to run the29/03/12 · Sales and operations planning (S&OP) is similar to investing in gold it gets a lot of attention during tough economic times Sure enough, the economic downturn over the past two years has seen a steady resurgence of companies pursuing S&OP initiatives Companies running S&OP improvement initiatives are aiming to achieve the overarching benefits of improved service01/06/19 · Sales & Operations Planning (S&OP) is the process by which we bring together all the plans for the business (Customers, Sales, Marketing, Development, Manufacturing, Sourcing, and Financial) into one integrated set of tactical plans S&OP gives management the ability to direct its business to achieve a sustainable competitive advantage

Solved Answer Briefly Chapter 13 This Chapter Addresses Chegg Com

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

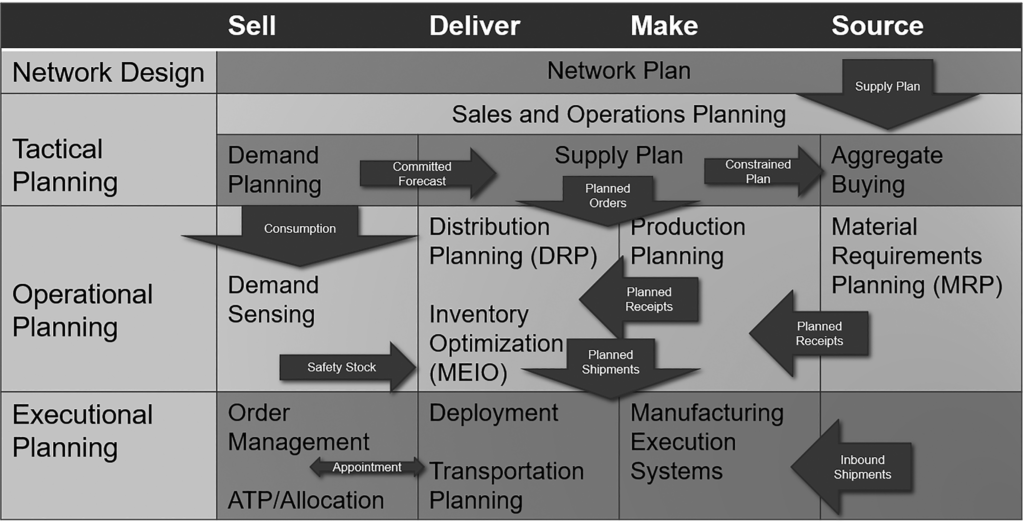

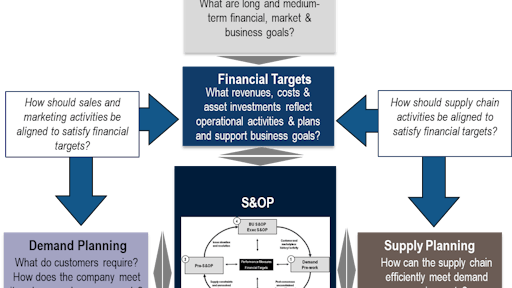

01/04/13 · 1 Sales & Operations Planning An Introduction Sales & Operations Planning An Introduction 2 S&OP Overview 3 The S&OP process was first developed in the1980's 1980's 1990's 00's Today S&OP evolved from supply chain execution activities such as MRP (material requirements planning) Today, S&OP is used across the Global 1000 405/02/ · S&OP, when done right, is a tactical process The focus is to help companies to make tradeoffs in the period in the longer time duration (past the order and operational horizons) S&OP execution should not be confused with S&OP planning S&OP execution is an operational process of organizational alignment of S&OP plans Figure 2 Role of S&OP14/11/19 · Advanced S&OP stretches from nearerterm tactical planning to longerterm strategic and financial planning The S&OP process typically occurs on a monthly schedule to develop a consensus demand plan, a constrained supply plan, an inventory plan and a synchronized financial plan, followed by an executive meeting where alternatives are reviewed and the path forward is

Who Owns S Op By Accenture Strategy Guest Blogger

S Op Process

Execute your S&OP plan Enables your S&OP plan to drive operational plans and execution;Sales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity)24/03/21 · Often, the tactical or operational planning is done by a different group of people in the company who are disconnected from the S&OP output This misaligned planning is detrimental to a firm's financial performance, hence the need for strong alignment

Good Sales And Operations Planning Is No Longer Good Enough Bain Company

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

A weekly and monthly operations meeting S&OP is a process focused on the whole organisation ;Usually this manifests as S&OP meetings that are increasingly dedicated to addressing execution challenges, rather than looking forward S&OP loses its value as a strategic business planning function As S&OP gets mired in execution, business leadership loses focus on key supply chain metrics such future unit volumes and supply chain costs10/03/10 · There are two answers to that question First of all, S&OP typically deals with longer term concerns;

What Is S Op Sales And Operations Planning Explained Anaplan

What Is Sales Operations Planning Supply Chain Minded

Sales & Operations Planning Key Capabilities Process Orchestration – Define and manage your S&OP process(es) Version and scenario creation and management for simulation and whatif analysis;11/07/18 · The business plan S&OP provides a structure for planning to address mediumterm situations;S&OP develops a midrange plan to operations using input from top management The plan identifies key resources to achieve the firm's strategic objectives and goals, and is the basis of all subsequent material and labor resource decisions and for the master production schedule PUT S&OP INTO PRACTICE Imagine you are a senior supply chain manager at a smalltomedium

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

The Evolution Of Sales Operation Planning

11/09/17 · S&OP is a monthly management process It provides a link between strategy and execution that engages senior management in a tangible way to make decisions in order to balance company goals andProcuring equipment, adding capacity, updating of outsourcing strategies That being said, these activities typically have longer lead times14/07/16 · First, the S&OP process lead (the single person who champions the process – or the quarterback) is typically in planning, specifically supply planning Planning departments often vary in how they are structured, so sometimes demand planning leads the process Either way, the head of planning (demand or supply) is what I typically see in high performing S&OP processes

Sales And Operations Planning S Op Transform Your Business

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

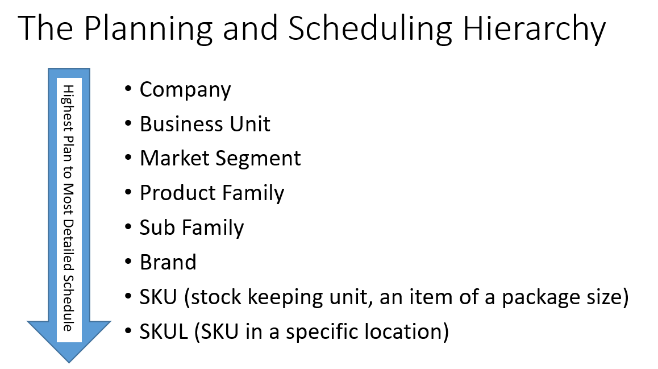

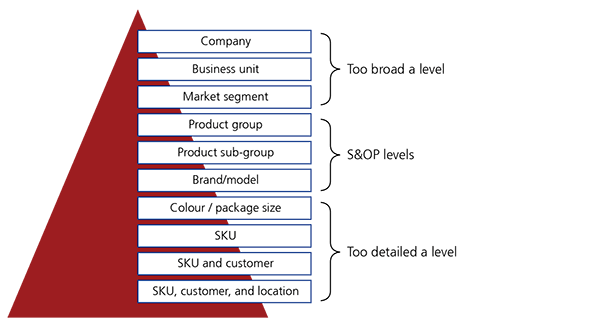

13/11/12 · All the planning is done in the segmentlevel S&OP process, which is made up of 26 horizontal processes Some of our clients find they have some of the 26 different horizontal planning processes already in place, at least in part The 26 are shown in Figure 54;14/01/ · S&OP Beyond supply and demand Many organizations lack the basic S&OP principles and could fail to keep pace in Regardless of how well an organization balances its demand and supply, it can always find room for improvement by integrating finance and other areas of the business, said Brad Stitt, executive vice president of supply chain management at Maine PointeS&OP stands for sales and operation plan and sales and operations planning at the same time It is both a plan and the process that creates, implements, monitors, and continuously improves the plan The S&OP process involves a series of meetings to meet a consensus A demand and production plans that reflect the results of demandside sensing and influencing activities and

Is Sales And Operations Planning A Digital Age Process Enterra Solutions

Seven Mistakes To Avoid In Sales And Operations Planning Supply Chain Shaman

Sales and Operations Planning (S&OP) process As discussed in Part I, S&OP has been receiving a lot of attention for the past couple of years There are a number of industrywide studies in the area Companies are recognizing its value in improving the tactical and operational planning to prepare the supply chain for meeting anticipated customer demand S&OP appears to be drivingSales and operations planning is typically led by senior management and is most often executed monthly It is an iterative process in which results from one planning cycle are compared with the next to provide management with trend information from across the businessSales and Operations Planning (S&OP) is a powerful approach that seeks to synchronize demand, capacity, and inventory When implemented well, S&OP is an efficient process that ensures cost and inventory optimizations while improving service levels

S Op Answering Six Fundamental Questions In One Graph

Isn T S Op Really Inventory Planning Navigate The Future

21/02/14 · Typically an S&OP project begins with a business case capturing the reasoning for initiating a project and quantifiable/ unquantifiable benefits case Next step will be designing the Tobe process;All are pulled together in the segment S&OP meetingS&OP defined The purpose of S&OP is to look ahead by several months or, playing the long game, thinking back to our golf analogy The time frame may vary by industry, but it's usually three to 18 months S&OP leadership works within the framework of longterm business goals, aligning its objectives accordingly Meanwhile, S&OP also provides

Seven Mistakes To Avoid In Sales And Operations Planning Supply Chain Shaman

Evaluation Of The Maturity Of The S Amp Op Process For A Written Materials Company A Case Study

10/07/19 · S upply planning is usually the last department to know about any changes to items including new product launches, distribution changes or even item discontinuations By including the product review in S&OP and as part of the supply review process, supply and inventory plans can be tied to the product strategy As a result, replenishment plans that were created on the27/02/15 · S&OP well done has at least four outcomes to provide visibility and support to the execution of a company vision It is in these four areas where S&OP needs to integrate and learn from other disciplines to improve as end to end business planning process 1 A feasible rolling forecast and budget27/10/18 · Embed Optimized Inventory Targets into the Supply Plan for S&OP;

My Take How We Screwed Up Sales And Operations Planning Supply Chain Shaman

My Take How We Screwed Up Sales And Operations Planning Supply Chain Shaman

Http//demandplanningcom//usingexceltopresentupdateforecastsatthedemandreview/ S&OP is a structured monthly process that aligns all functional areas under a unified set of assumptions to enable and coordinate decision making It integrates demand, supply, operations, and financial planning into one game plan for business22/02/21 · Here is the definition of S&OP from Wikipedia Sales and operations planning (S&OP) is an integrated business management process through which the executive/leadership team continually achieves focus, alignment, and synchronization among all functions of the organization Notice the words focus, alignment, and synchronization in the definitionFaster process Links underlying systems to provide a complete business view to speed up your S&OP process;

Solved Question 1 Sales And Operations Planning Deals Wit Chegg Com

Involving Execution Managers With Sales And Operations Planning Supply Chain 24 7

11/12/09 · S&OP – Planning Worksheet 66 S&OP – Information Flow S&OP Spreadsheet Demand Information Supply Information Summarised by family, sub family, by month, In lbs Order fill % Shortages KPI Actuals Prod Pln KPI Forecasts Actuals Util % OT Inventory Ad To Plan Capabilities Outages Constraints Production Distribution Inventory Issues Orders11/04/16 · Accurate Supply Planning By using the S&OP process, a company is able to be proactive, thus reducing last minute shuffling in the manufacturing and distribution process This allows an organization to address the supply chain's capacity constraints and response timing issues long before the end customer is affected Improved Risk Management When Sales & Operations planning

S Op And S Oe A Symbiotic Relationship

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Oracle Demantra Sales And Operations Planning User Guide

Sales And Operations Planning S Op

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

Sales And Operations Planning S Op 101 Smartsheet

Advanced Analytics For Sales Amp Operations Planning Analytics Magazine

Rough Cut Capacity Planning Why Is It Still And Will Be Important In The Future

Building The Business Case For Sales And Operations Planning S Op Supply Chain Link Blog Arkieva

What Is Sales And Operations Planning S Op Plex Demandcaster

S Op Answering Six Fundamental Questions In One Graph

Sales And Operations Planning Report Do You Get Surprises

What Is Sales And Operations Planning S Op Quora

Takeaways From An S Amp Op Conference

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

What Is S Op How S Op Works Demand Planning Com

What Is Sales Operational Planning Enchange

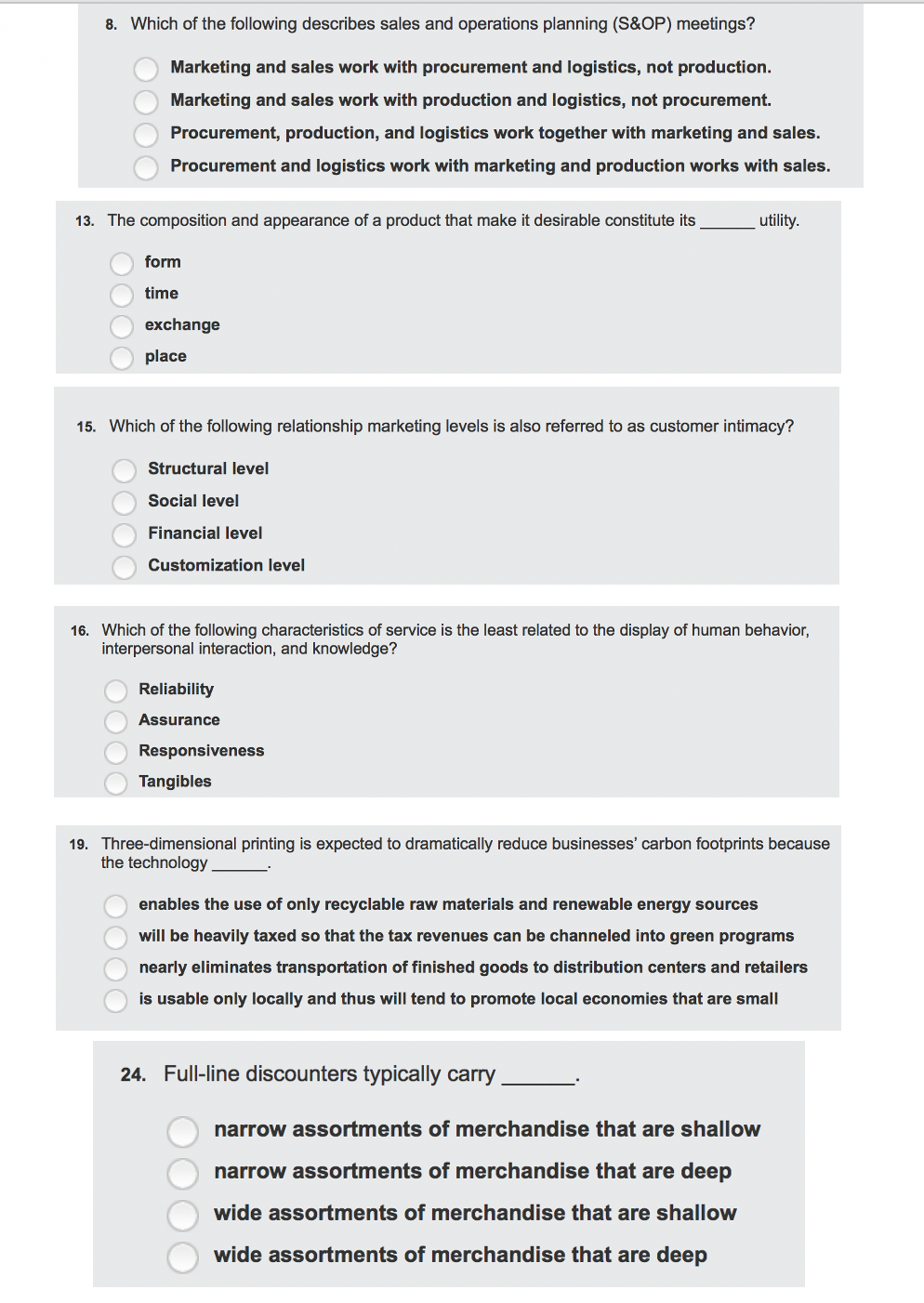

Solved 8 Which Of The Following Describes Sales And Oper Chegg Com

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Ultimate Guide To Sales And Operations Planning S Op In 21

What Is S Op Or Sales Operation Planning Sales And Operation Planning Definition And Steps

5 Reasons Why Sales And Operations Planning Is Important Scmdojo

What Is S Op How S Op Works Demand Planning Com

Working On Your S Op Tech Plex Demandcaster

How To Select The Best Sales And Operations Planning S Op Software For Your Business In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

Getting To The Next Level Of Integration With Sales And Operations Planning

A Case Method For Sales And Operations Planning A Learning Experience From Germany

Applied Sciences Free Full Text Predictive Sales And Operations Planning Based On A Statistical Treatment Of Demand To Increase Efficiency A Supply Chain Simulation Case Study Html

What Is Sales And Operations Planning S Op Plex Demandcaster

From S Op To Fully Integrated Business Planning John Galt Solutions

What Is S Op By Accenture Strategy Guest Blogger

Supply Chain Graphic Of The Week The S Op Process

Sales And Operations Planning S Op

R A Stahl Company Bob Stahl Of The R A Stahl Company Serves Industry With The Implementation Of Executive Sop Through Teaching Coaching And Guidance Both On Site And Virtually Through His Six Books Written With Tom Wallace He Is Known As The

Sales And Operations Planning Relex Solutions

Building The Business Case For Sales And Operations Planning S Op Supply Chain Link Blog Arkieva

Sales And Operations Planning Relex Solutions

Successfully Integrating S Op In Your Organization By Industrystar Medium

Achieve Excellence In Sales And Operations Planning Sapinsider

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

Sales And Operations Planning S Op 101 Smartsheet

Using Retail S Op To Make The Holiday Season Smoother And More Profitable

World Class Sales Operations Planning A Guide To Successful Implementation And Robust Execution Sheldon Donald Amazon Com Books

Achieve Excellence In Sales And Operations Planning Sapinsider

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Sales Operations Planning Consulting Supply Velocity

S Op Process

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Sales And Operations Planning S Op Meaning And Importance Marketing91

Sales And Operations Planning Relex Solutions

Sales And Operations Planning Myths Part 3 Supply Chain 24 7

Pdf Sales And Operations Planning S Op Concepts And Models Under Constraints Literature Review

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

Advanced Planning System As Support For Sales And Operation Planning Study In A Brazilian Automaker Springerlink

Why S Op Needs In Memory Computing Toolsgroup

S Op Families By Constraint

Sales And Operations Planning Explorescm

Good Sales And Operations Planning Is No Longer Good Enough Bain Company

Gartner Blog Network

A Common S Op Process For Your Business Helps Planning Learn About Logistics

Optimise Your Sales And Operations Planning S Op Slimstock Uk

Sales And Operations Planning S Op An Explainer

Optimize Sales And Operations Planning S Op With Slim4 Slimstock

Smoother Execution Through S Op Logistics Management

A Better Framework For Evaluating S Op Processes Manufacturing Net

Fixing An Overly Complicated Sales And Operational Planning Process Supply And Demand Chain Executive

7 Reasons Why S Ops Fail Supply Chain Analytics Planning Optimization Software Solvoyo

What Is S Op How S Op Works Demand Planning Com

Integrated Business Planning Ibp S Op Evolution Agile Innovation

0 件のコメント:

コメントを投稿